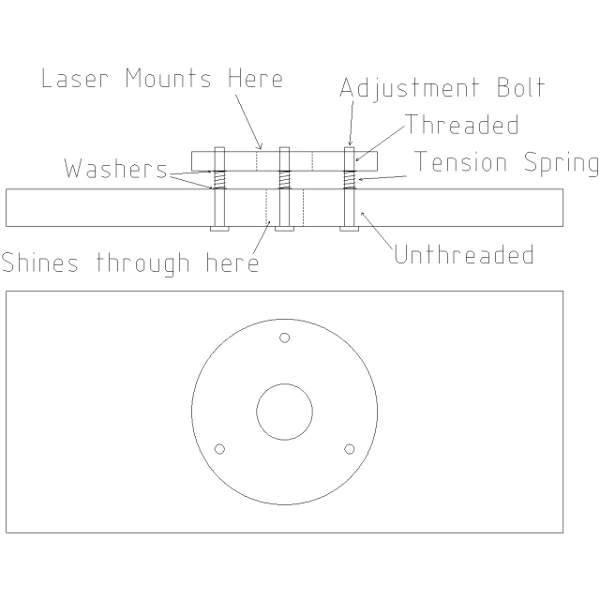

I woke up Thursday morning with the solution to my laser harp woes: to solve the problem of being able to align each of the lasers individually, I will put them all on tripod mounting platforms so that they can be adjusted. I came up with a few iterations of this design, shifting around the mechanism that holds the adjustment length. It is not clear to me which is the most practical solution. The main choices are a solution where the main part is threaded and one where a tension spring is used to hold the position. I might end up building a few of each to see which works out best. I happen to know someone with a laser cutter that could build some of these up for me, which would be really pretty. Here are some concept sketches I did (using qcad community edition, an open source CAD program) to demonstrate the options that are being considered.

-

Recent Posts

Follow Me:

Recent Comments

Archives

- August 2012

- August 2011

- July 2011

- May 2011

- April 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- July 2010

- June 2010

- May 2010

- April 2010

- March 2010

- February 2010

- January 2010

- December 2009

- November 2009

- October 2009

- July 2009

- June 2009

- April 2009

- March 2009

- February 2009

- January 2009

- November 2008

- October 2008

- September 2008

- August 2008

- July 2008

- June 2008

- May 2008

- April 2008

- March 2008

- February 2008

- January 2008

- December 2007

- November 2007

- October 2007

- September 2007

- August 2007

- July 2007

- June 2007

- May 2007

- April 2007

- March 2007

- February 2007

I’ve been dipping into your blog a bit lately – some really interesting stuff…

I solved the alignment issue with my first harp by mounting the receptors on a long strip of fridge magnet (magnetic metal would work too) and then putting each receptor on it’s own magnetic base, then I could nudge them around when needed.

Thanks Steve! That sounds like a pretty rad solution- much simpler than the tripod setup I have at each laser :-).